GRAPHALLOY®

GRAPHALLOY Increases Efficiency, Output and MTBF In Overhung Pumps

Upgrading to GRAPHALLOY bushings solved a major refinery’s Depropanizer feed pump vibration problems and seizures. The GRAPHALLOY upgrade resulted in increased pump efficiency, output and MTBF, in addition to significant cost savings.

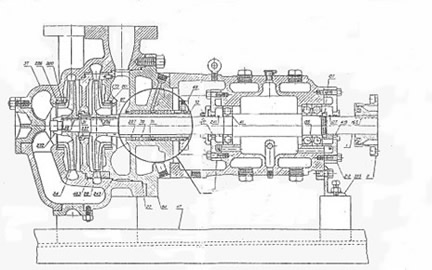

Depropanizer feed pumps in at Fluid Catalytic Cracking (FCC) unit at an East Coast refinery were having severe problems with vibration and mechanical wrecks. The two stage overhung pumps were experiencing excessive shaft deflection due to the high overhung rotor weight. The problem was compounded by flow instability. Unit throughput had been increased and the operating conditions were now well beyond the best efficiency point of one pump. The decision was then made to run two pumps in parallel, putting the flow in each pump well below the best efficiency point.

The pumps utilized steel wear rings, throat and interstage bushings which would rub, gall and, on occasion, seize. Pump life was between two weeks to two months between overhauls. Wear ring clearances were increased to try to minimize the risk of rubbing and seizure but this led to increased levels of vibration and interstage leakage. Vibrations levels were measured to be as high as 1.5 inches/second.

The refinery contacted the engineers at Graphite Metallizing. The two case rings, throat bushing and intermediate stage (diaphragm) bushings were replaced with GRAPHALLOY material. The clearances were reduced to less than half the original metal clearance.

A few years after the retrofit, the refinery experienced a major unit upset: a pump was run dry for as long as 30 minutes at 3560 rpm. However, the pump did not seize or wreck catastrophically because of the non-galling, self-lubricating qualities of the GRAPHALLOY rings.

Best of all, a significant increase in the output of these pumps was achieved as a result of the reduction in wear ring clearances using GRAPHALLOY. Refinery personnel estimated that the best efficiency flow rate and total output from the pumps increased by about 15%. This increase in output allowed the refinery to meet the required flow rates with one pump, eliminating parallel pump operation at flows well below BEP. In addition, vibration levels were reduced by more than 80%.

7/1/2018

|