GRAPHALLOY®

Maintenance-Free Bearings for Tunnel Ovens

GRAPHALLOY® self-lubricating bearing can operate from -450 °F to +1000 °F, handle caustic washdowns, and are maintenance-free.

FDA Acceptable Grades are available

A Terrible Maintenance Situation

A Bakery Oven OEM was using rolling element bearings on the conveyor circuit of a tunnel oven. The bearings were used for various styles of wire conveyor belting on the idler shafts as well as the support rollers. The belt speed is generally slow and the temperature can range from 450 °F to 650 °F.

To reach these bearings, mechanics would have to crawl over the oven belt when the machine was shut down, thus causing damage to the belting and rollers. This made greasing these bearings a continuous problem. To reach these bearings, mechanics would have to crawl over the oven belt when the machine was shut down, thus causing damage to the belting and rollers. This made greasing these bearings a continuous problem.

They had tried installing automatic lubrication systems with mixed results, and, to make matters worse, these lubrication systems were causing cleanliness and contamination issues.

Another issue was that the bearings faced caustic washdowns that rusted even the new 400 series stainless ball bearings they were trying. In some applications, bearing life was as little as 2 weeks. Once the bearings failed, the idler rolls would not run and this could cause premature wear on the conveyor belts. All of this resulted in more downtime and difficult trips into the machine for the mechanics.

A Solution For All of the Above A Solution For All of the Above

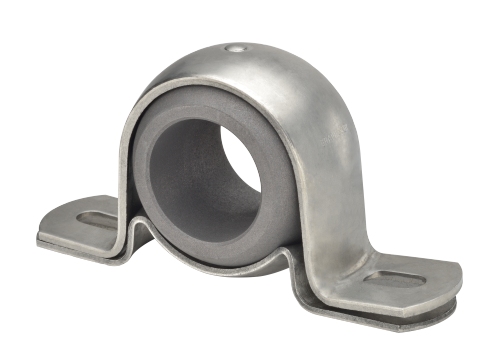

They were researching other solutions when they discovered Graphalloy. Graphalloy self-lubricating bushing materials thrive in high temperature environments, handle caustic washdowns, and are the perfect solution for areas that are difficult to access. After discussions with Graphalloy engineers, the company decided to test Graphalloy’s stainless steel pillow blocks with copper-grade bushing inserts.

The Graphalloy material has eliminated the need for greasing, and the material and the stainless components are standing up well to continuous washdown. These Graphalloy bushings have been running for several years with no issues.

Do you have a troublesome, high temperature or caustic washdown application? If so, tell us about it by clicking here and our sales engineers will contact you. Or, if you prefer, you may contact us directly.

Click here to download this case history Click here to download this case history

|