GRAPHALLOY® Bushings

Solve A Sump Pump Problem

The Problem

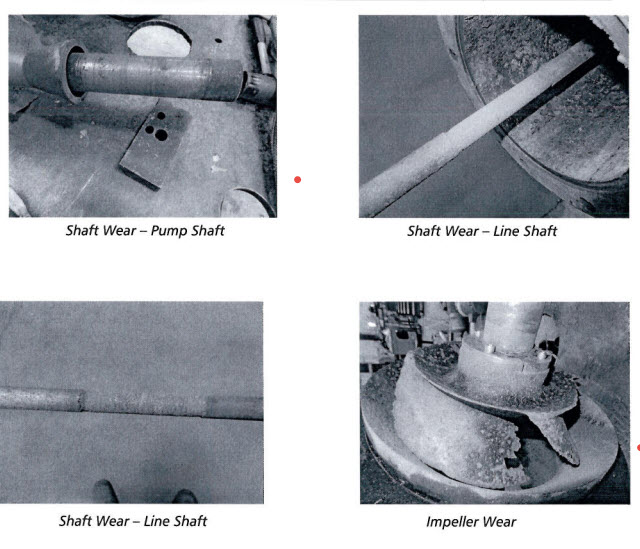

A major refinery was experiencing frequent bearing failures in their vertical oily wastewater sump pumps, Goulds VIT-FF 8X14 DHLQ-1 stage. The bronze packing box and line shaft bearings were wearing out within two months of service, damaging the shaft and causing leakage through the packing at the stuffing box.

The bearing failure was also causing an environmental issue when the hydrocarbon/water slime leaked into the ground.

The Solution

The refinery engineers discussed solutions/upgrades with the engineers at Graphite Metallizing, the manufacture of GRAPHALLOY self-lubricating bushings. The Graphite Metallizing engineers suggested they replace the bronze bearings with GRAPHALLOY bronze-grade bushings, which included a spiral groove to channel away any possible abrasives in the pumpage.

GRAPHALLOY is non-galling (unlike the bronze), so the bushings were designed with a tighter fit to the shaft to reduce vibration.

Graphalloy is self-lubricating, so bushings that aren't submerged during start up, especially the stuffing box bushing, are able to maintain lubrication.

The Results

It has been over two years since Graphalloy has been installed in the pumps and one of the refinery's Rotating Equipment Engineers said the pumps are "working great".

Upgrading to GRAPHALLOY bushings solved the problem.