GRAPHALLOY® Wear Parts

For Greater Pump Efficiency

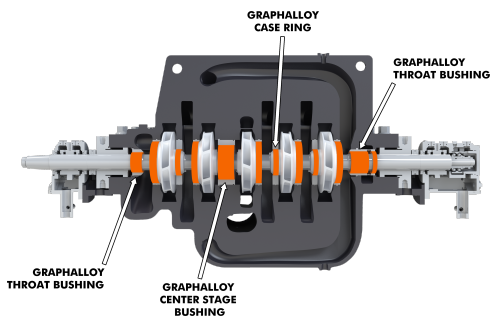

Tighter running clearances typically lead to increased pump efficiency due to the reduction of leakage across the wear parts (case rings and bushings). Tighter running clearances typically lead to increased pump efficiency due to the reduction of leakage across the wear parts (case rings and bushings).

But not all materials can work with tight running clearances. Metal wear parts are prone to galling and seizing if there is contact with the rotating parts, so designers (and API standards) provide wider clearances to prevent this crash possibility.

Plastic wear parts often have very high CTEs (coefficient of thermal expansion) which causes them to grow – rapidly – if there is contact while operating. Worse, the plastic is typically an insulator and so the heat is trapped in the part causing rapid growth or deformation or even melting during contact. So designers also end up requiring wider running clearances. Some plastics have carbon fibers which might result in a very low CTE – this causes another set of problems especially at high temperatures where the parts may become loose in a pump housing that has grown due to thermal expansion of the metal parts.

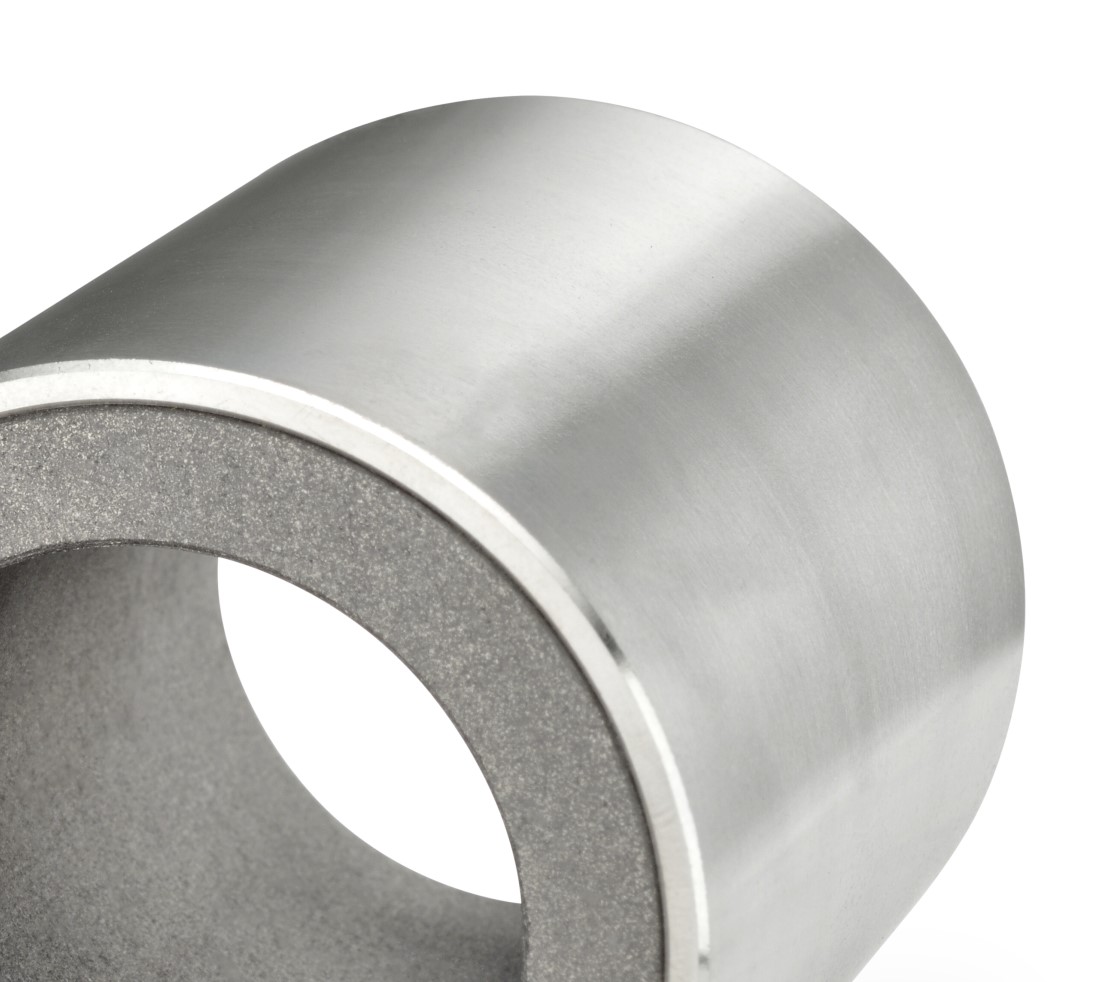

Graphalloy wear parts can be designed with tight running clearances due to the material's unique qualities. The Graphalloy bushing and wear ring material is a graphite-metal alloy. Graphalloy is a non-galling material that can handle temperature extremes. The metal pulls heat away from the shaft and adds wear resistance. The result is a long-lasting, self-lubricating, non-galling pump component. This means that Graphalloy wear parts can be designed at as low as half of API's recommended running clearance.

Graphalloy has a low coefficient of thermal expansion. This property means that a designer can install the Graphalloy part with a significant press fit AND the Graphalloy will “follow” the size changes of the metal parts of the pump. This means you can have a tight clearance over a very wide range of temperatures (from start up at ambient to running at a high temperature).

Because Graphalloy allows tighter clearances on the wear parts, it leads to improved efficiency. A pump OEM ran tests comparing Graphalloy wear parts and chrome wear parts. The Graphalloy wear parts improved pump efficiency by 2%. And for a large pump with hundreds or thousands of HP 2% can mean thousands of dollars annually in power savings for your plant- for each pump.

With all the new initiatives for greater pump efficiencies, using a material that allows you to reduce wear part running clearances, through its unique qualities, is an important upgrade to your pumps.

04/7/2022 |