GRAPHALLOY® Bearings

High-Temperature Pillow Blocks Provide Over 26 Years of Reliable Service

- Application: Paper mill dryer section operating at elevated temperature and low speed

- Dryer temperature: 350°F

- Shaft speed: 30 RPM

Background

In late 2025, Graphalloy was contacted by the facilities and maintenance manager of a global manufacturer of specialty engineered products used in thermal, acoustical, and filtration/separation applications. The company designs and manufactures advanced technical nonwoven, membrane, and composite materials.

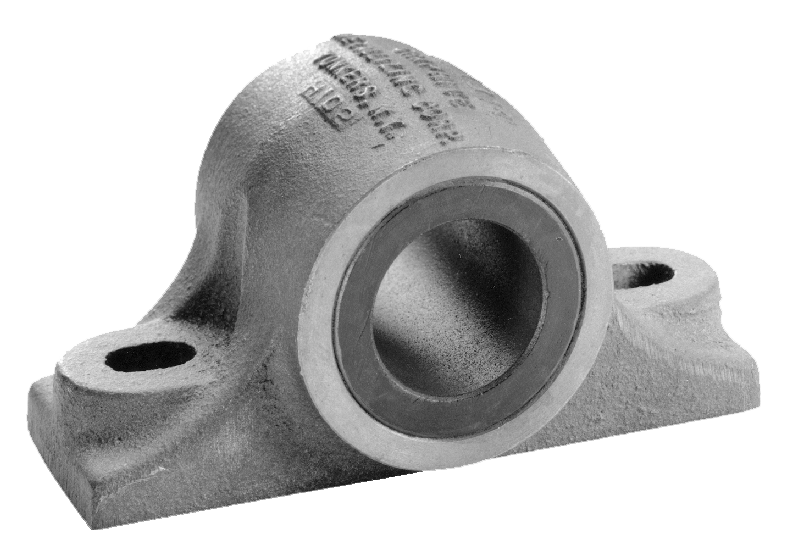

The manager reached out regarding existing high-temperature pillow blocks installed in a paper mill dryer application and shared a photo of the installation. The bearings in service were Graphalloy Type 163 pillow block assemblies operating under demanding conditions.

A review of historical records showed that the original pillow blocks had been supplied through a bearing distributor in August of 1999. Despite continuous exposure to operating temperatures of 350°F, the bearings had remained in service for more than 26 years.

Solution

After reviewing the application details and installation photo, a Graphalloy engineer confirmed that the existing pedestal mounts, used to raise the bearing centerline height, could remain in place. New Type 163 pillow block assemblies were specified as direct replacements, allowing the bearings to be installed without modifying surrounding equipment.

Results

Eight new Graphalloy high-temperature pillow blocks were installed, restoring the dryer application with minimal downtime and no changes to the pedestal configuration.

Conclusion

Graphalloy bearings continue to demonstrate exceptional longevity in high-temperature, low-speed applications. In some cases, performance is best measured not in hours or months, but in decades.

For more information, contact us at sales@graphalloy.com.