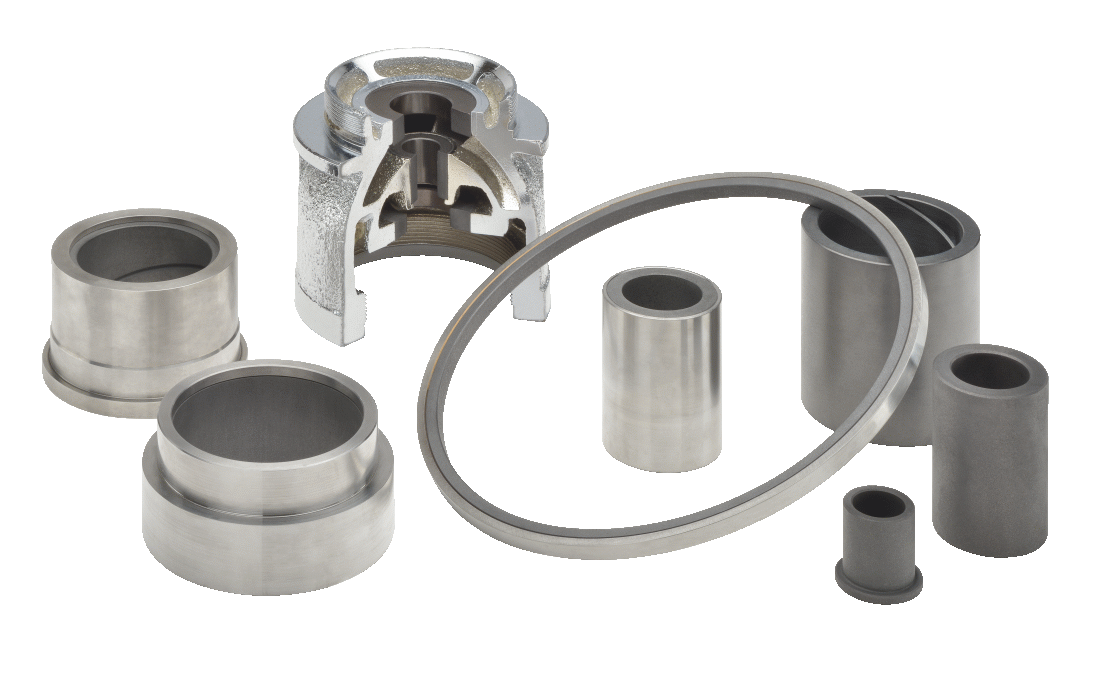

GRAPHALLOY® Bushings

Succeed in Difficult Ethane/ CO2 Pump

A pump repair company was recently looking at a Ethane / CO2 pump that had gone into upthrust and failed during supercritical fluid service. This is a well injection pump with fluid at 50oF to 95oF, and the specific gravity varies from 0.395 to 0.48. Ethane is 78% of the mix, with CO2 the rest.

Upon inspection of the entire pump, the Graphalloy bearings that had been installed over 2 years ago showed almost no wear and did not need replacement.

The pump is pumping a mix of ethane and CO2 that is kept above the triple point. The fluid is compressible and as work is done on the fluid the temperature increases. This can create all sorts of problems for the pump, but the customer agreed that the Graphalloy bushings work very well in this service.

Graphalloy bushings are a standard for pumps in this service. Low lubricity fluids such as Ethane and CO2 can be especially difficult for metallic bearings because the hydrodynamic film provided by these fluids is unable to provide enough lubrication, which can lead to metal-on-metal contact, galling or seizing of the pump. Graphalloy bushings are self-lubricating and non-galling. Using GRAPHALLOY bearings and wear rings allows tighter clearances, improving reliability, lowering vibration and increasing efficiency in vertical and horizontal pumps.

Read about Graphalloy's Success in an application that experienced frequent dry running

|