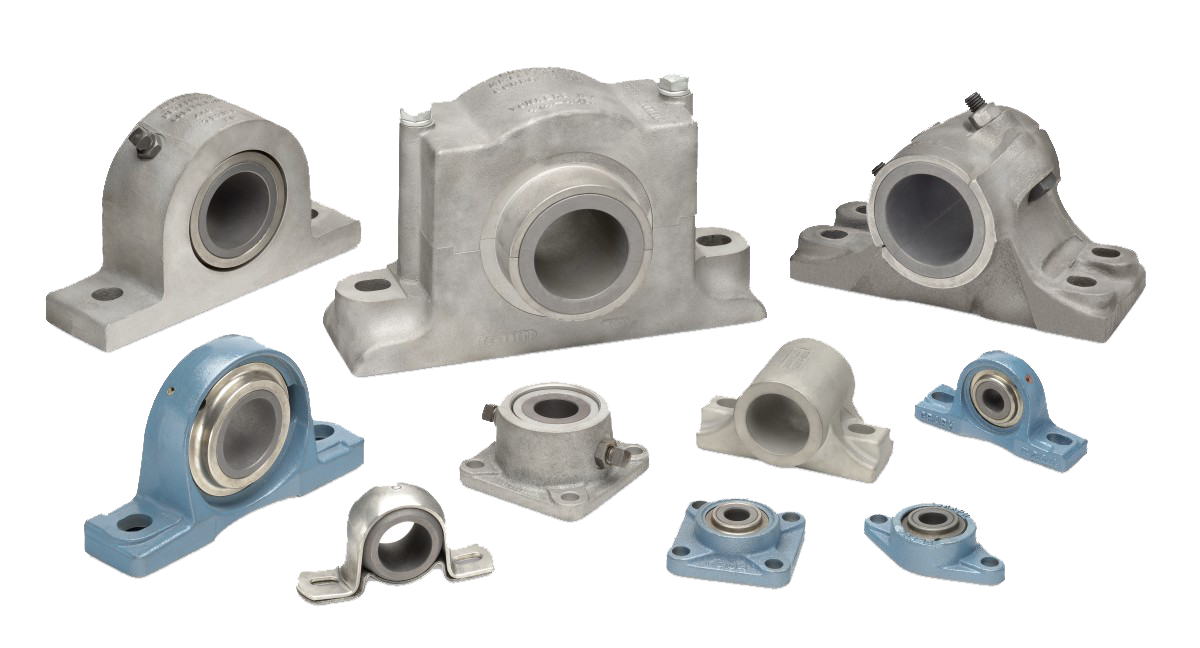

GRAPHALLOY® Bearings

Why Graphalloy Bearings Are a Game-Changer for Seafood Processing

Seafood processing environments are among the toughest on equipment. Between freezing temperatures, saltwater exposure, and constant washdowns, most bearings struggle to survive, let alone thrive. Graphalloy Bearings were made for this.

Whether it’s a chilled conveyor line or a brine tank, Graphalloy bearings operate smoothly where traditional bearings seize, swell, or corrode. Here’s why seafood producers trust Graphalloy.

- Performs in Cryogenic Conditions

- Our bearings don’t just tolerate cold — they excel in it. Graphalloy maintains performance even at cryogenic temperatures, ensuring reliability in freezing lines and storage environments.

- Washdown & Salt Brine Resistant

- Engineered to withstand frequent washdowns, salt brine, and harsh cleaning chemicals. Graphalloy doesn’t absorb moisture and won’t degrade, making it perfect for frequent washdown cycles and corrosive marine environments.

- Self-Lubricating, Maintenance-Free

- With no grease to contaminate food lines or wear out, Graphalloy keeps running — reducing downtime and eliminating the need for manual re-lubrication.

- FDA Acceptable Grades Available

- Safe for direct food contact. Trusted in hygienic processing. Ready for inspection.

If you’re looking for a bearing solution that can handle seafood processing from dock to deep freeze, Graphalloy is built for it.

Explore our solutions here.

|