GRAPHALLOY®

Bearings for Refineries

Summary

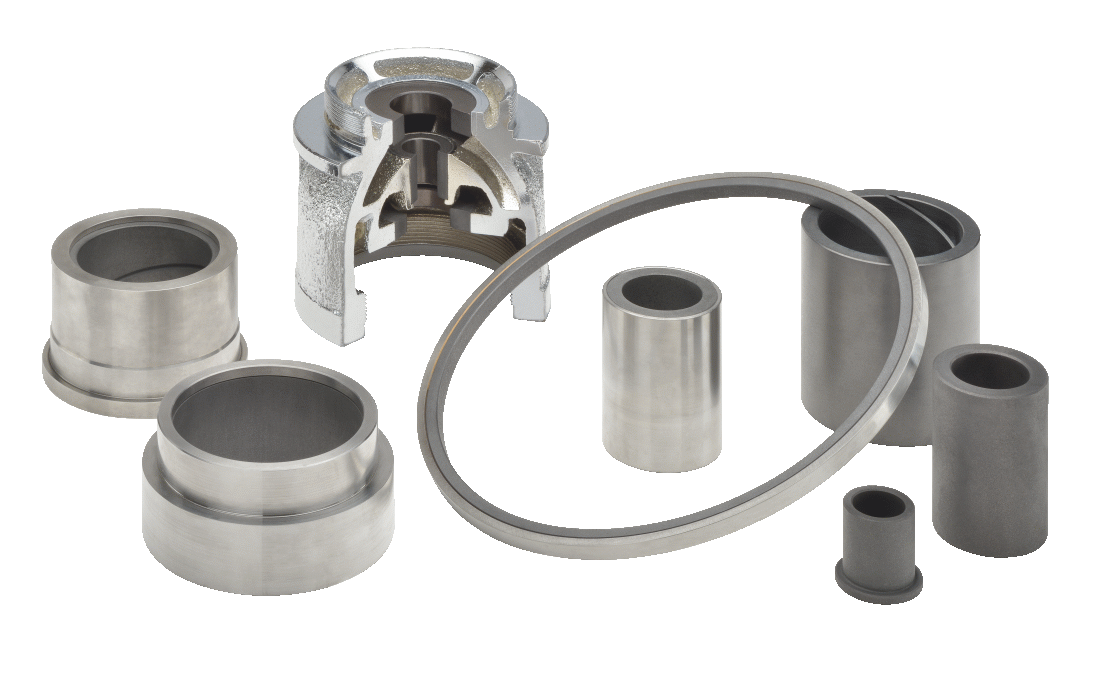

Refineries have many applications where metal, hard carbon, and plastic bearings/bushings will not work due to high temperatures, cryogenic temperatures, run-dry scenarios, or low lubricity fluids. From dampers to problem pumps, GRAPHALLOY materials offer install-and-forget solutions and improved efficiency.

Why Graphalloy for Refineries

GRAPHALLOY materials, made from graphite-metal alloys, have the following advantages:

- Self-lubricating: Require no grease or oil, maintenance-free

- Temperature Range: Operate from -450°F to +1000°F (-265°C to +535°C)

- Submerged: Operate in submerged conditions and hostile liquids. Will not swell. No lubricant to wash out.

- Non-galling: Will not gall when running against metal rotating parts

- Improved Pump Efficiency: Allow for tighter running clearances due to self-lubricating and non-galling features

- Lower Vibration: Due to tighter running clearances

Refinery Applications for Graphalloy

- Reactor and Agitator Bearings

- Damper Bearings

- Valve Bushings

- Throat Bushings

- Bowl Bushings

- Case Wear Rings

- Stage Bushings

Ready to upgrade your refinery's reliability? Chat with us now, email or use our inquiry form

Graphalloy Case Histories in Refineries

Throttle Bushing, Overhung Pump

A Gulf Coast refinery was using standard throat bushings, which often have a running clearance of 0.040" to 0.060". This wide running clearance in the throat bushing can cause premature failure of the mechanical seal. GRAPHALLOY solved this problem with a bushing with a much tighter running clearance of 0.010", which in effect creates a throttle bushing, thereby increasing mechanical seal life. GRAPHALLOY bushings are able to achieve this tight running clearance due to their non-galling quality.

Refinery Damper Bearings

This Midwest refinery had tried both carbon bearings and greased bearings for dampers in the vacuum heater, air pre-heater, and coker units (high temperature, slow rotation applications). The carbon bearings were sticking and the greased bearings could not be easily maintained. They decided to try maintenance-free, self-lubricating Graphalloy bearings in inserts for pillow blocks and flange blocks. The bearings have been working for over a year and the customer is pleased at the difference in performance.

Lean Amine Vertical Turbine Pump

A refinery in the Middle East used a multi-stage, heavy duty vertical turbine pump (VS1). This type of pump is used for a variety of severe services. The pump was fitted with hard carbon/antimony bushings. The bushings scored the shaft during flashing and run dry episodes, due to the hardness of the carbon. They replaced these with Graphalloy graphite/Babbitt bushings, which are kinder to the rotating parts and can survive run dry/flashing due to their non-galling, self-lubricating qualities. This also allows tighter clearances, improving efficiency. The customer said the pump is back in service and running very well.

Bushings for Ethylene Pumps

Ethylene is a very light hydrocarbon that creates problems in pump operation. Because of its low viscosity, ethylene provides minimal lubrication to the rotating parts of the pump. The pumps in this Texas refinery were failing 2–4 times a year at a cost of $75,000 per pump. The OEM pump repair shop recommended GRAPHALLOY wear parts based on their success retrofitting other ethylene pumps. Graphalloy allows the rotating parts to contact without the danger of galling and seizing. All four pumps were retrofitted. In the three years since their installation, none of the converted pumps have failed. In addition, the clearances did not open up in that time.

Specify with Confidence

With more than 100 material grades, Graphite Metallizing Corporation engineers can match a bearing to virtually any nuclear water chemistry or temperature profile. Every sleeve bearing, flange block, or thrust washer is machined in Yonkers, NY under ISO 9001 quality control.