GRAPHALLOY

®

Automotive Supplier’s Change to GRAPHALLOY

Bearings

Increases Production in High Temperature Furnace

Production has increased by several thousand units per month as a result of

eliminating failures in high temperature grease lubricated cam followers. A

change to GRAPHALLOY, a graphite/metal alloy bearing material, has helped TI

Automotive increase production in a heat shrink furnace that is critical to

their operation.

Before the change to GRAPHALLOY cam followers, the conveyor bearings failed

about once a month because the heat of the furnace evaporated their high

temperature grease lubricant. It took about half a day to cool down the furnace,

change the bearings and reheat the furnace so that production could be

restarted.

As one step in their production process TI Automotive applies heat shrinkable

sleeves to brake and fuel lines. The sleeves protect areas of the steel lines

that might be vulnerable to objects thrown up by the tires. The company’s plant

in Ashley, Indiana, applies heat-shrinkable tubing to the lines and then places

them on a conveyor that feeds them into a furnace heated to 350oF where the

plastic shrinks to conform to the steel brake and fuel lines

"The new bearings have already lasted for about five years without a single

failure," said Harry Foley, Process Improvement Engineer for TI Automotive based

in Ashley, Indiana. "They have eliminated the downtime that formerly plagued

this operation. Since we installed them I estimate we’ve saved well over 300

hours of production downtime that would have been lost if we had kept the old

bearings."

Automotive industry standard

The double-walled Bundyweld tube produced by TI Automotive has become the

automotive industry standard for brake and fuel lines and the company has also

pioneered quick connectors, anti-abrasion sleeves, corrosion coatings and

bundling. A continuous strip of copper plated steel is wrapped and bonded to

form a double-walled tube designed to carry fluids at high pressure, as well as

to provide greater assurance against leakage in low-pressure applications. The

latest manufacturing techniques have allowed for precise control of the

temperature and brazing conditions and can be coupled to other continuous

processes, such as coating.

Coatings enhance the proven integrity of Bundyweld tubing, giving protection

against corrosion and abrasion in extreme environmental conditions. All

underbody components, including the brake line, have the potential to be struck

by objects thrown up by the tires. TI Automotive provides extra protection

against damage by specifying the addition of a plastic sleeve to the tube areas

most vulnerable to stone damage. Sleeves can be applied to either add further

abrasion resistance in areas of high potential impact or to give

noise/vibration/harshness reduction benefits.

Protecting critical brake lines

When heated, the sleeve shrinks to conform to the size and shape of the

underlying material. The company uses a special furnace to increase the

productivity of the heating operation. The oven is open on both sides and has a

conveyor system that runs through the furnace and extends a distance on either

side. This highly efficient production heating process is capable of producing

between 3000 and 5000 parts per day depending on customer order levels.

Problems with downtime

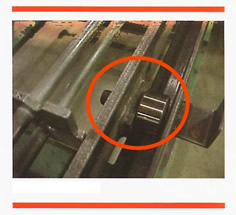

In the past, the conveyor rode on ten standard cam roll bearings that were

lubricated with high temperature grease. The problem was that the heat caused

the grease to deteriorate and led to early bearing failure, typically after

about one month of use. The bearing replacement process typically took about

four hours, which resulted in a production loss of between 1500 and 2500 pieces.

In an effort to solve the problem, Foley tried many different lubricants but was

never able to find one that would last any longer than a month. He also tried

stainless steel bearings without any lubricant but found that they were also

unable to stand up to the application.

Then Foley searched an industrial directory for high temperature bearings and

found GRAPHALLOY, a high temperature graphite-metal alloy bearing material.

GRAPHALLOY combines the properties of graphite and metal. The graphite structure

can be compared to a deck of cards with individual layers that are able to

easily slide off the deck. This phenomenon gives the material a self-lubricating

ability that is matched by no other material. External lubricants are simply not

necessary. GRAPHALLOY is graphite filled with a metal impregnant to enhance the

chemical, mechanical and tribological properties of the material.

Solving the problem

Foley called up the bearing manufacturer and soon received an application

data sheet asking for information such as the inside and outside diameter of the

bearing, temperature of the application, operating speeds and loads, etc. He

filled out the form and faxed it back to Graphite Metallizing. The company

responded with a proposal that included drawings, operating specifications and

procedures. The bearing manufacturer said that they had no doubt that their

bearings would easily stand up to the application. Foley purchased 10 of the

bearings and installed them in the conveyors.

"The performance of the new bearings has been simply amazing," Foley said.

"We have gone from a situation where we had to change bearings every month to

one where the bearings never need changing. They have already been in operation

for more than five years and not a single one has failed nor have we seen any

signs of problems. The result is that we have been able to significantly reduce

production downtime. During the periods when our operators used to have to sit

on their hands waiting for bearings to be changed, they are now pumping out

parts."

Self-lubricating properties

GRAPHALLOY bearings are self-lubricating because when the bearing is rubbed

against metal or ceramics, a microscopically thin graphite film is quickly laid

down on the shaft. This low-friction film plays a vital role in controlling

temperature rise during operation. The formation of a proper transfer film

requires the presence of absorbable vapors such as water. Grades with special

impregnants are available for those rare applications in which no suitable

vapors are present.

This unique self-lubricating bushing material requires no grease or oil,

survives run-dry conditions, and eliminates galling and seizing in hot and dry

conditions. GRAPHALLOY is ideally suited to applications where temperatures are

too high to permit the use of oil or other lubricants because there are no

lubricants to congeal or solidify. GRAPHALLOY will not soften at high

temperatures or extrude under load. Many grades are suitable for temperatures to

750o F in air, where oil-based lubricants burn off or oxidize and plastics fail.

Special grades give good service up to 1000o F and higher in non-oxidizing

atmospheres.

The material provides other properties that are beneficial in this and other

applications. It maintains its integrity even when submerged in hostile liquids

such as acids, alkalies, hydrocarbons, black liquor, and liquid gases. The

material provides a constant, low coefficient of friction rather than just a

surface layer, helping to protect against catastrophic failure. Lubrication is

maintained even during linear motion; lubricant is not drawn out and dust is not

pulled in. GRAPHALLOY wear components also improve reliability under conditions

such as low speed operation, frequent starts and stops and switch-overs from

standby to continuous running. GRAPHALLOY bushings are available in over 100

grades of material in any desired size or geometry, including cylindrical with

or without grooves, flange or double flange, split and metal-backed. Grades and

design are engineered to best serve the application.

|