GRAPHALLOY® Bearings

Outperform Greased Bearings and Plastic Bearings in the Textile Industry

Bearings That Survive Where Textiles Push the Limits

Textile processing isn't kind to bearings. The combination of heat, chemicals, and constant motion destroys traditional lubricated or polymer components. When lubricants burn off or polymers soften, downtime begins — and maintenance teams get another emergency call.

GRAPHALLOY® bearings were designed for this kind of punishment. The graphite-metal alloy provides built-in lubrication that won't evaporate, melt, or wash away. That means no grease, no seals, and no failure from lubricant loss.

Real-World Textile Results

- Dyeing Tank, Europe: Bearings exposed to soda and sulfite solution failed prematurely. Graphalloy replacements lasted five times longer, eliminating sudden breakdowns.

- Carpet Drying Oven, USA: Operating at 375–400 °F, standard bearings wore rapidly. Graphalloy flange blocks ran for six months with no measurable wear.

- Hot Roll Laminator: Rollers carrying 2,500 lb per set at 450 °F showed stable performance using Graphalloy pillow blocks, with zero maintenance required.

The Engineering Advantage

Graphalloy bearings resist corrosion, operate dry, and handle both high load and temperature extremes. For textile engineers, that means:

- Reduced maintenance cycles

- Improved uptime and product throughput

- Predictable performance in aggressive conditions

In environments where other bearings fail, Graphalloy continues running. That reliability is what plant managers value most — performance that proves itself quietly, shift after shift.

Detailed Case Histories

Dyeing Tanks - 5X Increase in Bearing Longevity

A European facility was using equipment to move material through dyeing tanks, which contained water, soda, and sulfite. The name-brand polymer material bearings were failing due to exposure to the mixture. Graphalloy bushings replaced these polymer bushings, and lasted 5x as long and eliminated the risk of sudden, catastrophic failures.

Carpet Drying Ovens - 6 Months and No Wear

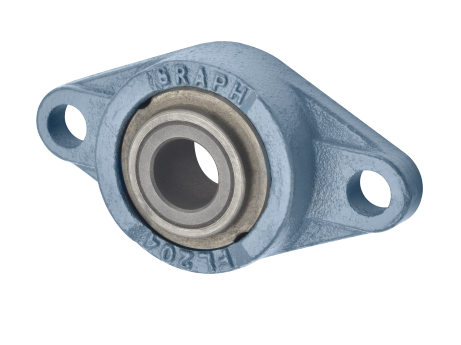

A customer had bearing issues in their natural gas carpet drying ovens. The carpets are loaded into an oven where a backing is applied and dried. The oven temperature range is 375-400ºF. The ovens were facing constant issues with bearings failures. Once a week, a 2-man crew had to inspect and grease or replace bearings. The customer purchased 2 of our 845 flange blocks to test. The bearings showed no wear after 6 months in service, and the customer has placed additional orders for their new oven.

Nonwoven Hot Rollers - Maintenance-Free Service

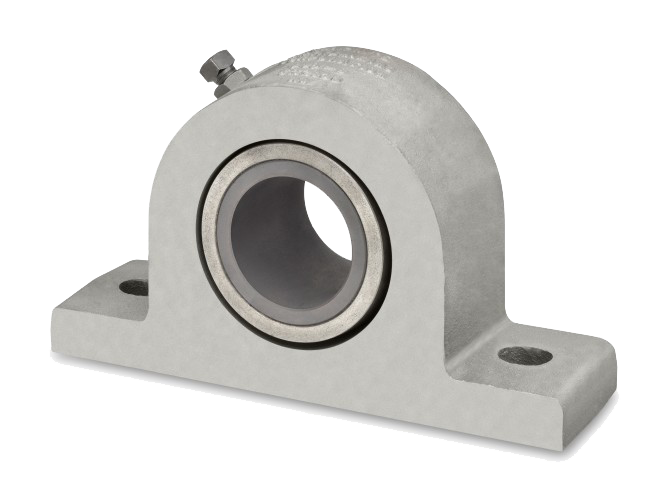

A maintenance manager at a facility that manufactures specialty nonwovens needed high temperature bearings. The facility uses large rollers for the hot roll presses, where hot oil is circulated through the rollers for the lamination process of their nonwoven textile materials. The temperature is 450ºF, the speed is 8-20 RPM and the load is 2,500 LB for each set of two bushings. He installed two sets of Graphalloy type 448 pillow blocks to support the rollers. They have been impressed with the maintenance-free aspect of Graphalloy bearings, and impressed that they "seem unaffected by the high temperature". They will continue to replace the roller bearings with Graphalloy bearings whenever the roller bearings fail.

10/17/2025