GRAPHALLOY® Bushings

Successful in Screw Compressors

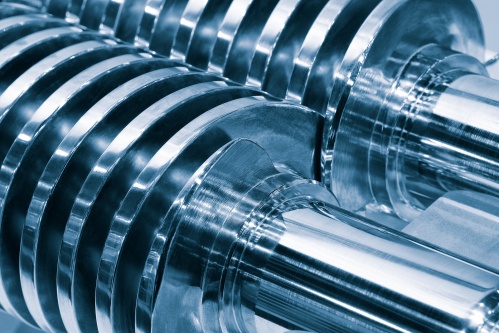

Graphite Metallizing Corporation, the manufacturer of self-lubricating GRAPHALLOY® bushing materials, announces the success of Graphalloy bushings in screw compressors. Screw compressors act to compress gases using male and female rotors that rotate in opposite directions. As the gas progresses along the rotors it is compressed as the volume space between the rotors decreases, thereby creating compressed gas at the discharge. Graphite Metallizing Corporation, the manufacturer of self-lubricating GRAPHALLOY® bushing materials, announces the success of Graphalloy bushings in screw compressors. Screw compressors act to compress gases using male and female rotors that rotate in opposite directions. As the gas progresses along the rotors it is compressed as the volume space between the rotors decreases, thereby creating compressed gas at the discharge.

In this particular application, Graphalloy Bushings are used in a screw compressor in hydrogen gas service. It is a high speed, low load application for the bushings. The pump repair shop had originally tried aluminum bushings, which failed, then plain bronze bushings, which also failed. They then tried Graphalloy Bushings, which have been successful in this application.

Graphalloy Bushings offer solutions in places where traditional bearing lubricants will not work, including high temperature applications, clean environments, submerged operation applications, and more. The Graphalloy material is self-lubricating, non-galling, can handle low lubricity service and can withstand temperatures from -400°F (-240°C) to +1000°F (+535°C).

The Graphalloy material is used in many low lubricity pumps due to its self-lubricating and non-galling features, and screw compressors offer one more successful pump application for Graphalloy.

Graphalloy, a graphite-metal alloy, is available in over 100 grades with specific properties that meet a wide range of engineering solutions and specifications. Graphalloy bearings have operated for 20 years and longer in some applications. Common applications for Graphalloy bushings include pumps, wastewater, ovens, dryers, dampers/louvers, kilns, conveyors, submerged, and more.

|