GRAPHALLOY® Flange Blocks Improve Damper Reliability in Ammonia Facility SMR Operations

Background

In November 2024, the manager of a nitrogen company's ammonia production facility contacted GRAPHALLOY to discuss upgrading the damper bearings on their steam methane reformers. The existing roller-element damper bearings were showing wear and proving unreliable in the high-temperature, high-contaminant operating environment typical of ammonia production.

The customer had previously converted similar damper assemblies in their Tringen 1 anhydrous ammonia plant in 2022. Those units were equipped with GRAPHALLOY 4-bolt flange blocks, which have now provided three years of continuous, trouble-free operation. Based on that success, they were interested in implementing the same upgrade on their current ammonia plant's damper actuators.

The Project

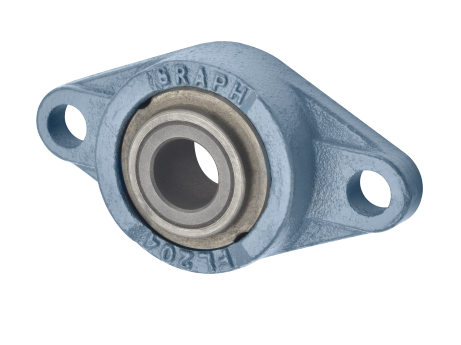

The facility's damper system uses pneumatically actuated mechanisms to open and close louvered panels via a lever arm. The customer's goal for this project was to completely replace the existing flange block assemblies with GRAPHALLOY flange blocks fitted with copper-grade GRAPHALLOY bushings. Before ordering, the customer requested a virtual call to review the operating requirements and confirm bushing specifications.

The Order

Following that discussion, the customer placed an order for seventy total units: twenty type 845F2 assemblies and fifty additional assemblies of a second size. Installation was completed during the first week of March 2025.

Operating Conditions

- Equipment: Damper actuator on steam methane reformers (SMRs) in ammonia plant

- Load: Approximately 300 lbs

- Speed: Slow, partial rotation

- Temperature: 300 to 420°F (hot, combustible air environment)

Results

After installation, a follow-up check-in confirmed that the bushings were performing well. "The bushings are working fine, and we appreciated the support on this project," the customer reported. Due to the location of the components, photographs of the installed assemblies were difficult to obtain, though the previously provided images of the roller-element bearings give clear context for the application.

Additional Applications

This facility also sources GRAPHALLOY bushings and case wear rings for its boiler feedwater and condensate pumps, further demonstrating the material's reliability across multiple high-temperature, demanding service environments within the plant.