GRAPHALLOY® Bearings

In a Wind Tunnel Valve

This company has developed a new style of control valve (shutter valve). They are targeting this for a wide variety of industries including oil and gas, aerospace, chemical, power plants, and water management.

In development, they have primarily used polymer bushings but higher temperatures led them to try Graphalloy.

They are using Graphalloy thrust washers, cut in ¼ inch sections. An engineer at the company said that their onsite valves tested well for many thousands of cycles which prompted them to install additional parts on a customer’s full-size unit for testing.

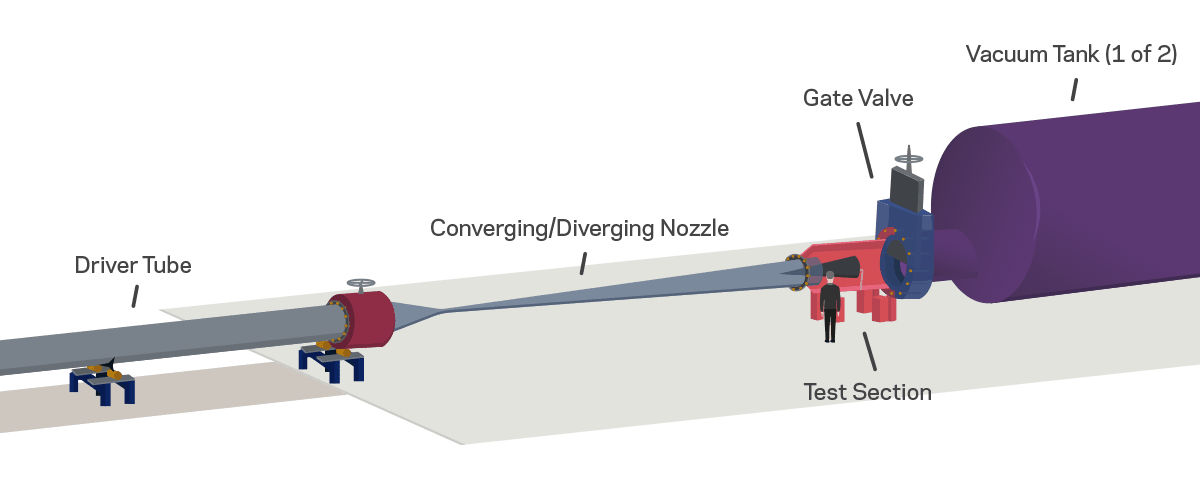

The valve where the Graphalloy washers are installed is in the “test section” of the hypersonic, Mach 6 wind tunnel at research university to test air flow at hypersonic speeds. A stainless steel driver tube that will shoot air heated to 600°F sitson supports running about 80 yards. Two large vacuum tanks that will pull the air from the other end are also in place. In between will be the special nozzleand test section, which will be enclosed inside an extension built onto the current laboratory, the engineer said that after over one year, the Graphalloy thrust washers are “running very well with no issues”. tanks that will pull the air from the other end are also in place. In between will be the special nozzleand test section, which will be enclosed inside an extension built onto the current laboratory, the engineer said that after over one year, the Graphalloy thrust washers are “running very well with no issues”.

|