GRAPHALLOY®

Bearings Run Over 6 Years in a Potato Chip Fryer

The maintenance manager at a major snack food manufacturer checked the Graphalloy bushings installed on the paddle wheels of their potato chip fryer and “realized they had been running strong for over 6 years!”

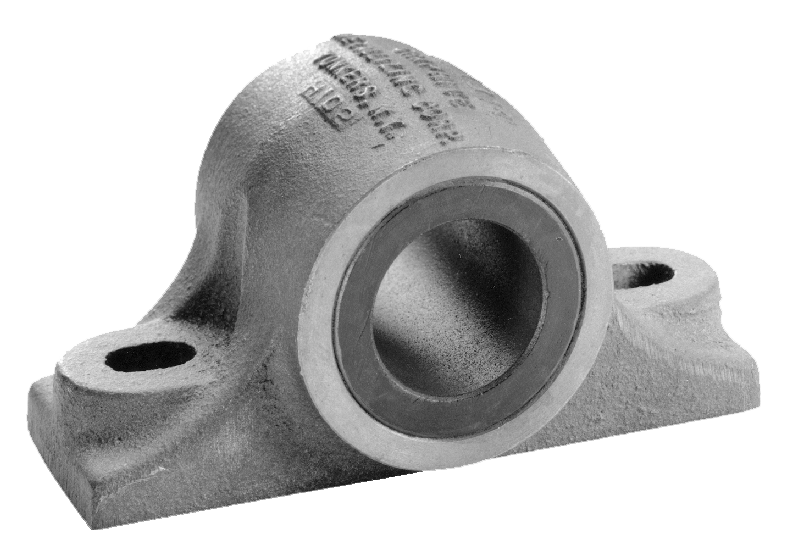

Back in 2014, the company had installed a new fryer as part of a reshoring initiative. Based on prior successes with Graphalloy, they installed Graphalloy type 963 2-bolt stainless steel pillow blocks with FDA-acceptable bushings on the paddle wheel drive shaft, running at 50 RPM.

Back in 2014, the company had installed a new fryer as part of a reshoring initiative. Based on prior successes with Graphalloy, they installed Graphalloy type 963 2-bolt stainless steel pillow blocks with FDA-acceptable bushings on the paddle wheel drive shaft, running at 50 RPM.

These paddle wheels operate like the ones on a steamboat — except instead of moving water, they keep potato chips submerged in 375°F oil for the perfect amount of time. The plant runs 6,000 pounds of potatoes per hour, meaning those bearings work non-stop.

When they realized the bearings had been operating for 6 years without failure, they asked: “What other equipment should we install these on?”

Why It Worked

- No grease required — eliminating risk of product contamination.

- No maintenance — ran continuously for 6 years without intervention.

- Longevity — replaced “run-to-failure” with reliable, trusted uptime.

In October, during a planned shutdown, additional Graphalloy bearings were installed for the second paddle wheel drive. Even with housing modifications, the investment paid off: “Here it is October of 2020, and still no signs of wear.”

Encouraged, the plant also ordered Graphalloy bushings for their corn washer, where greased bearings were failing under harsh sanitization. The self-lubricating bushings withstood caustic wash-down chemicals, avoiding rust contamination and extending reliability across multiple applications.

Encouraged, the plant also ordered Graphalloy bushings for their corn washer, where greased bearings were failing under harsh sanitization. The self-lubricating bushings withstood caustic wash-down chemicals, avoiding rust contamination and extending reliability across multiple applications.

The maintenance team now considers Graphalloy bearings standard equipment across their facility. Reliable operation, zero grease, and long service life mean more uptime and less maintenance stress.