GRAPHALLOY® Retrofit Delivers 15% More Flow and 80% Less Vibration in Overhung FCC Pumps

1. The Headache

Pushing an FCC unit for higher rates pushed its Depropanizer feed pumps well past their best-efficiency point. Shaft deflection spiked, steel wear rings rubbed, and vibration hit 1.5 in/s. Mean time between failures? Sometimes as short as two weeks.

2. The Switch

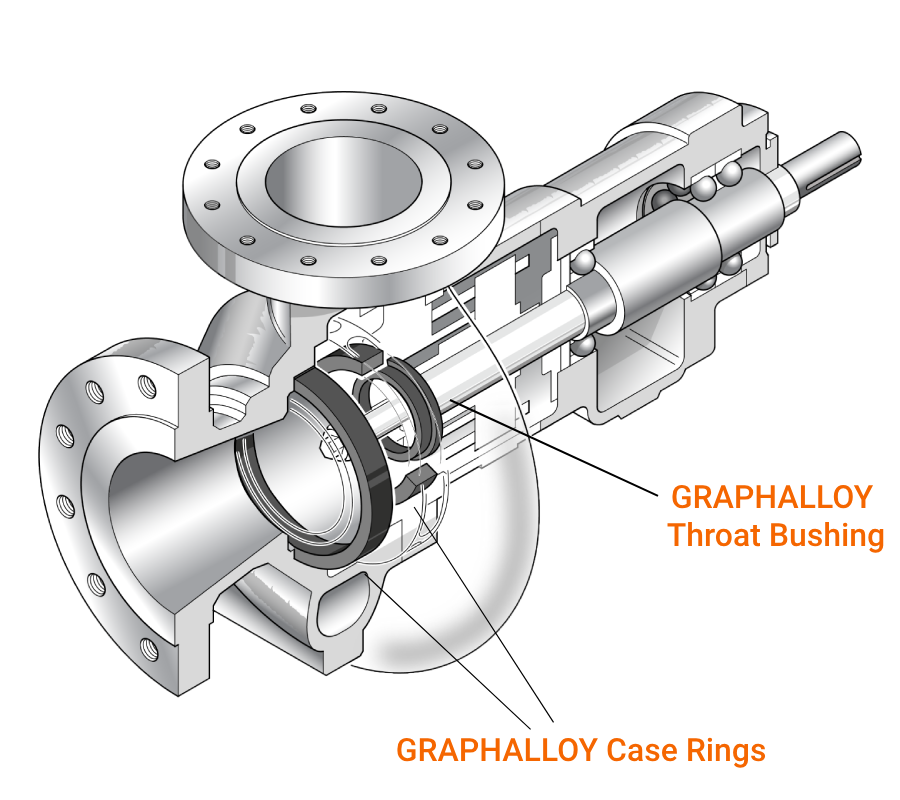

Plant engineers replaced the two case rings, throat bushing, and interstage bushings with GRAPHALLOY grade GGC—a graphite/metal alloy that won’t gall and needs no external lubrication. Clearances were cut to less than half the old metal gaps.

3. The Payoff

One real-world stress test tells the whole story: after a 30-minute dry-run during a unit upset, the pump restarted without damage.

4. Why It Worked

• Self-lubricating matrix survives dry-run, flashing, or cavitation.

• Non-galling contact lets you tighten clearances instead of opening them.

• Chemical and thermal tolerance suits hot propane/propylene mixtures.

5. Bottom Line

With tighter clearances, the refinery meets target throughput on a single pump, slashes vibration, and saves on spares and power. GRAPHALLOY turned a maintenance headache into a reliable asset—exactly what you need when every barrel counts.

Thinking about a similar retrofit? Drop us a line at sales@graphalloy.com or visit graphalloy.com.